News

How to Choose the Best Grease for Your Heavy Equipment

One of the most important things you can do to maintain your heavy machinery is to grease it regularly. Grease not only extends the life of the machine, but it also prevents contamination and increases machine performance. Grease prevents joints from sticking and helps to ensure the pins and bushings don't become worn.

Here is our detailed guide to choosing the best grease for your heavy equipment.

Choosing the Best Grease

1. Don't use the same type of grease for all of your machines and parts

It may be tempting to select one type of grease for all of your equipment. This can work some of time, but if you're looking to extend the life of your equipment, you'll want to tailor each type of grease to the type of machine and your specific jobsite conditions.

Also, different parts of a machine may require different types of grease, depending on their operating temperature.

If your equipment uses an auto-lubrication system, you may need a lighter grease, such as an NLGI #0 or even an NLGI #00, in some instances.

2. Check grease recommendations in your equipment manual

One of the first places to check when deciding which grease to use is your machine's operation manual. While not all manuals go into specifics about greasing, they'll include a general recommendation. This is a great place to start.

3. Use NLGI #2 grease in the summer

When it's hot outside, grease tends to become thinner, so it's important to use a thicker grease in the summer. Look for grease that has a high viscosity.

This is especially important for our clients in Southern Nevada and Arizona, where temperatures in the summer can regularly exceed 100 degrees. We recommend using a NLGI #2 (Polyurea or multipurpose) grease.

What does NLGI mean? NLGI stands for the National Lubricating Grease Institute and is the institution that certifies grease. Grease can range from NLGI #000 to NLGI #6, but the most common is NLGI #2 because it can be used for a wide temperature range.

Read: How to Prepare Your Heavy Equipment for Summer.

4. Use an NLGI #1 grease during winter

When temperatures fall below 60 degrees Fahrenheit, it is a good idea to use NLGI #1 grease or a synthetic grease. This will make the equipment easier to operate.

Make sure you have a good grease gun or grease pumping system during the cold winter months or you may have difficulty ensuring the grease reaches the zerk fittings and flows properly through the joints.

Read: 5 Best Practices for Winterizing Your Heavy Equipment.

5. Use a different grease in wet conditions

If a particular job requires that your machines are exposed to wet conditions, like rivers, heavy rain or the ocean, it may be a good idea to use a marine grease. Marine greases have lithium complex thickeners and can help prevent rust and protect against damage from salt.

6. Base your grease choices on the equipment application

If a job requires you to apply a lot of pressure to a machine, it may be a good idea to use a grease with a molybdenum disulfide (moly). The additive helps the grease get into small machine pins and bushings. If the parts aren't greased sufficiently enough, welding can occur.

Types of Grease and When to Use Them

All grease is made up of a fluid lubricant that is comprised of either mineral oil or synthetic oil and a thickener. Some may also include additives. Below are four main categories.

Basic Greases:

"Moly" grease — Inexpensive but a good quality grease. It's good for machines with moving joints—like a loader or backhoe.

Next Level Up:

Polyurea or (multipurpose) grease—This type of grease is good for parts that reach a high temperature, as this is a "high temp grease." Machines that have spindles or rotating grooves can get very hot and a polyurea grease won't break down as quickly as other types of grease.

Higher-End Greases

Synthetic grease—This type of grease is more expensive—It's almost three times the cost of a basic grease—but it lasts longer than a petroleum-based grease.

Specialty Greases

There are numerous specific greases that are made for particular gear boxes and applications. High impact greases, for example, are made for breakers (hammers), because they are formulated to withstand pounding. Make sure to read the grease tube label carefully to ensure you have the right one, as specialty greases have specific uses. They are not for general use.

Greasing Maintenance Tips:

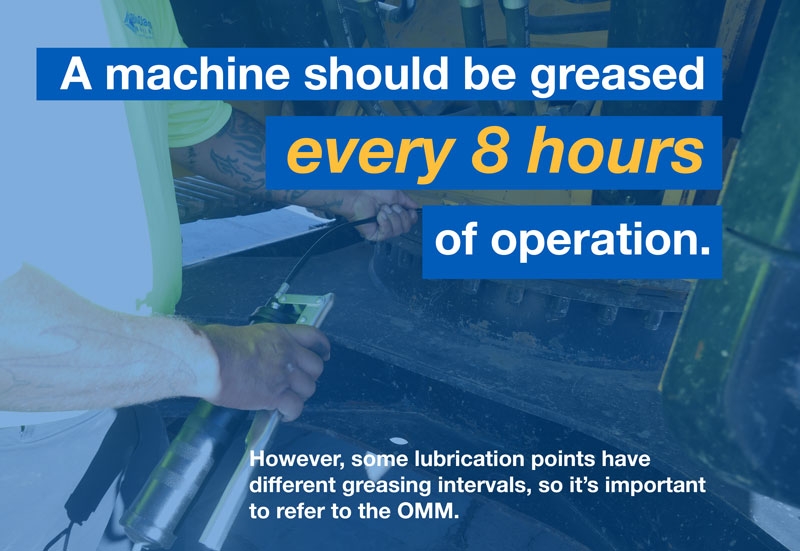

- While greasing daily is ideal, at minimum, you should be greasing every eight hours of operation. However, some lubrication points have different greasing intervals, so it's important to refer to the OMM. Make sure to grease all the grease points around the machine.

- Don't wait until you hear a grinding noise to re-grease. It's important that you don't skip greasing intervals. Skipping greasing may save you money in the short term, but grinding can produce metal flakes in the bearing or bushing that can damage the machine.

- Remove old grease before adding new grease. The old grease needs to be completely removed before using a new grease, because some greases are not compatible with one another due to their different thickeners.

- Keep zerks clean—Dirt can become caked onto fittings that are slick with grease, so before you re-grease, make sure to clean off the zerks in order to prevent accidentally pushing dirt into the bearing. If you don't, the dirt buildup can result in equipment failure.

- Don't overuse the grease gun on the bearings—Grease guns produce up to 15,000 psi per stroke (or shot), but a bearing lip seal can only handle up to 500 psi. If you apply, say, 20 shots of grease to a bearing, you may overfill the bearing cavity, which can force the grease outside of the seals when the equipment heats up. This can lead to contamination as well as moisture buildup.

About Blue Diamond Machinery: Blue Diamond Machinery is an independently-owned heavy equipment rental and sales company. We are headquartered in Las Vegas and service all of Nevada, Utah, and Idaho. Our growing team of employees have over 65 years in the construction industry. Visit www.heavyequipmentrentals.com to learn more.

FREE Guide to Buying and Selling Heavy Equipment

Enter your details to receive our complimentary ebook