News

If you're new to operating a dozer, perhaps the most important thing you'll want to do is to get a sense of how the machine should look, feel, sound and smell (yes, smell) when it's running smoothly. This takes time, so don't stress if you don't have a handle on it right away. After you've clocked in several days in the driver's seat, you should be able to have an intuitive feel for how the machine should run. But in the meantime, below are several bulldozer operating tips to keep you safe and your machine running as smoothly and efficiently as possible.

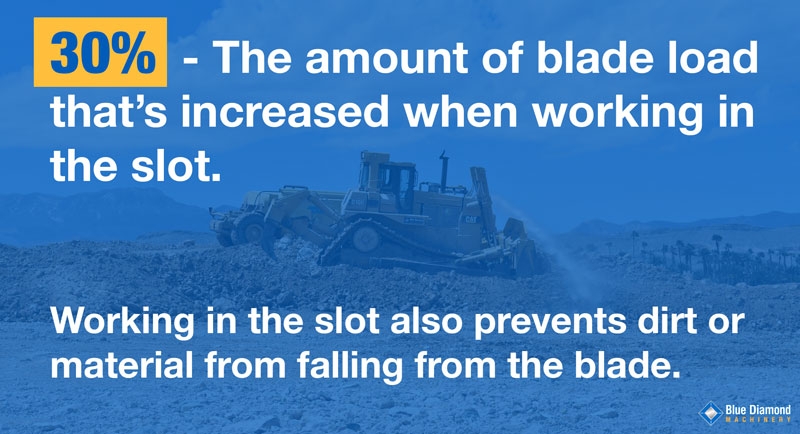

1. Work in the slot

It's important to work in the slot by dozing front to back. Working in the slot helps to decrease dirt or material from spilling from the blade. It can also help to increase the blade load by up to 30 percent. When digging a slot, dig until you've reached the height of the blade and then move on to the next slot.

2. Doze from the front and work backwards

If you're looking to maximize productivity and decrease undercarriage wear, we recommend dozing front to back. We've found this to work well because when you work front to back, you limit the amount of time you spend operating the machine in reverse. The less time you spend driving backwards, the more you can slow down wear on the track.

Here's how to do it:

1. Start behind the the spot where you intend to cut—about two tractor lenghts. On the first pass, operate the dozer in first gear, aiming to fill the blade as fast as possible and start a spoil pile (if you're operating a small or medium-sized tractor, you can shift to second gear). A good goal is to flill the blade within two tractor lengths or less. Next, reverse the machine until you are two tractor lengths behind where you started the first pass; This is where you'll want to begin your second pass. As you move through the second pass, steer the machine through the same slot that you made in the first pass. Continue doing this—reversing and then extending your starting point—until you've reached your desired slot length.

2. When you're ready to start a second slot, reverse until you are approximately two tractor lenths from the spoil. Then move the machine until you are next to the first slot. You should aim to keep a distance of about one third of a blade width between the edge of the blade and the first slot.

3. Front-to-back dozing can reduce the amount of time you spend operating in reverse by 38 percent. Instead of backing up for the entire cut, you're only backing up for the length of the previous push and then an additional two tractor lengths.

3. Check the track tension

When track chains are tight, they can wear up to three times faster than they would normally. While you should check with your operator's manual for specifics, the general rule of the thumb is that if your track has a carrier roller, the sag should be two inches.

Here is how to meaure the sag:

1. Slow to a stop—Don't use your brakes.

2. Lay a straight edge over the grousers or stretch a string from the idler to the sproket.

3. Measure the distance between the lowest point of the sag and the grouser tip.

4. Measure the lowest point of each valley on both sides of the carrier lower and calculate the average.

While there is no set interval track-chain tension adjustments, the chain tension should be adjusted whenever a change in weather or environmental conditions occurs.

For example, the track-chain tension should be checked when any of the following conditions occur:

- It rains

- It becomes windy

- The machine runs into puddles of water

- The air temperature increases

These conditions can cause mud or debris to pack into the sprockets. By adjusting the chain tension, you can prevent the loose chain from binding in front of the idler.

50 percent of undercarriage wear can be reduced by maintaining proper track-chain tension. According to field surveys conducted by Caterpillar, however, 20 percent of tracks are too tight.

4. Use short cuts

Dozer operators often assume that long cuts are better, but the opposite is actually true. A dozer blade can only hold a finite amount of dirt. If you can continue to push forward after the blade is full, the dirt will fall to the sides of the blade and you'll have windows that you'll need to go back and move. What's more, when the blade is full, you're cease being able to cut and are only pushing dirt in front of the blade. Long cuts waste fuel and can lead to undercarriage wear and track slip. Every bulldozer, no matter how small or big it is, should be able to accumulate a full blade load within two tractor lengths or less.

Make every hour of operation count and use shorter cuts. This will help save energy and time.

5. Work up and down slopes whenever possible

Operating a machine on a hillside can be a dangerous job, which is why we recommend crawler dozer operators work slowly on slopes and keep attachments low. We also suggest working up and down on slopes in order to prevent rollerovers. While newer machines have hydrostatic transmissions, older machines have torque converters, which may not have an automatic holdback. Thus, it's best to avoid changing gears and costing in neutral while going downhill.

6. Check oil and coolant every morning and evening

While falls more into the maintenance side, it's good to get into the habit of checking the coolant and engine and hydraulic oils each and every morning before work resumes. The transmission and engine oil should be checked again at the end of the work day. This should also include a check of air filters and well as the grease fittings, such as the swing frame zerks.

Read: How to Choose the Best Grease for Your Heavy Equipment.

FREE Guide to Buying and Selling Heavy Equipment

Enter your details to receive our complimentary ebook